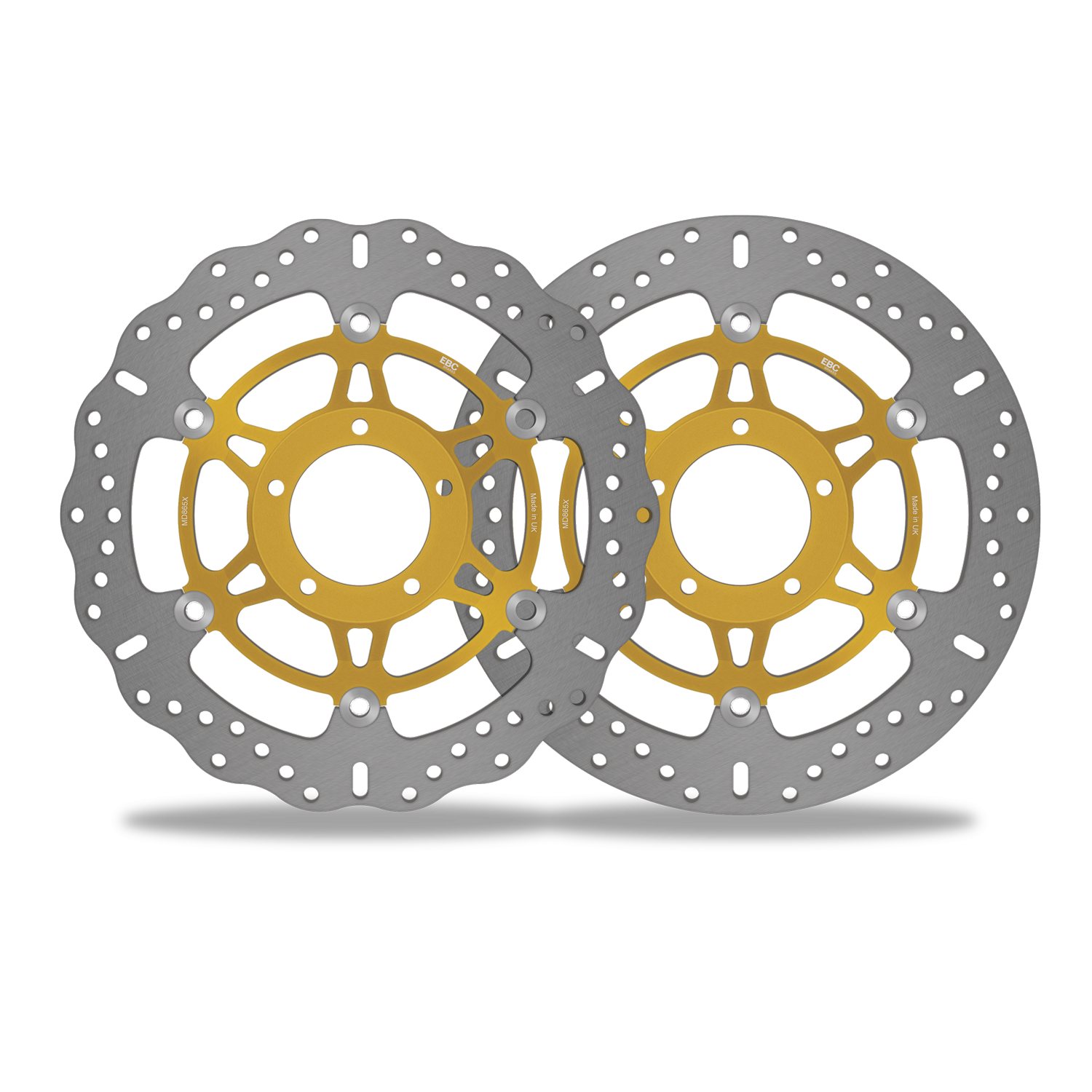

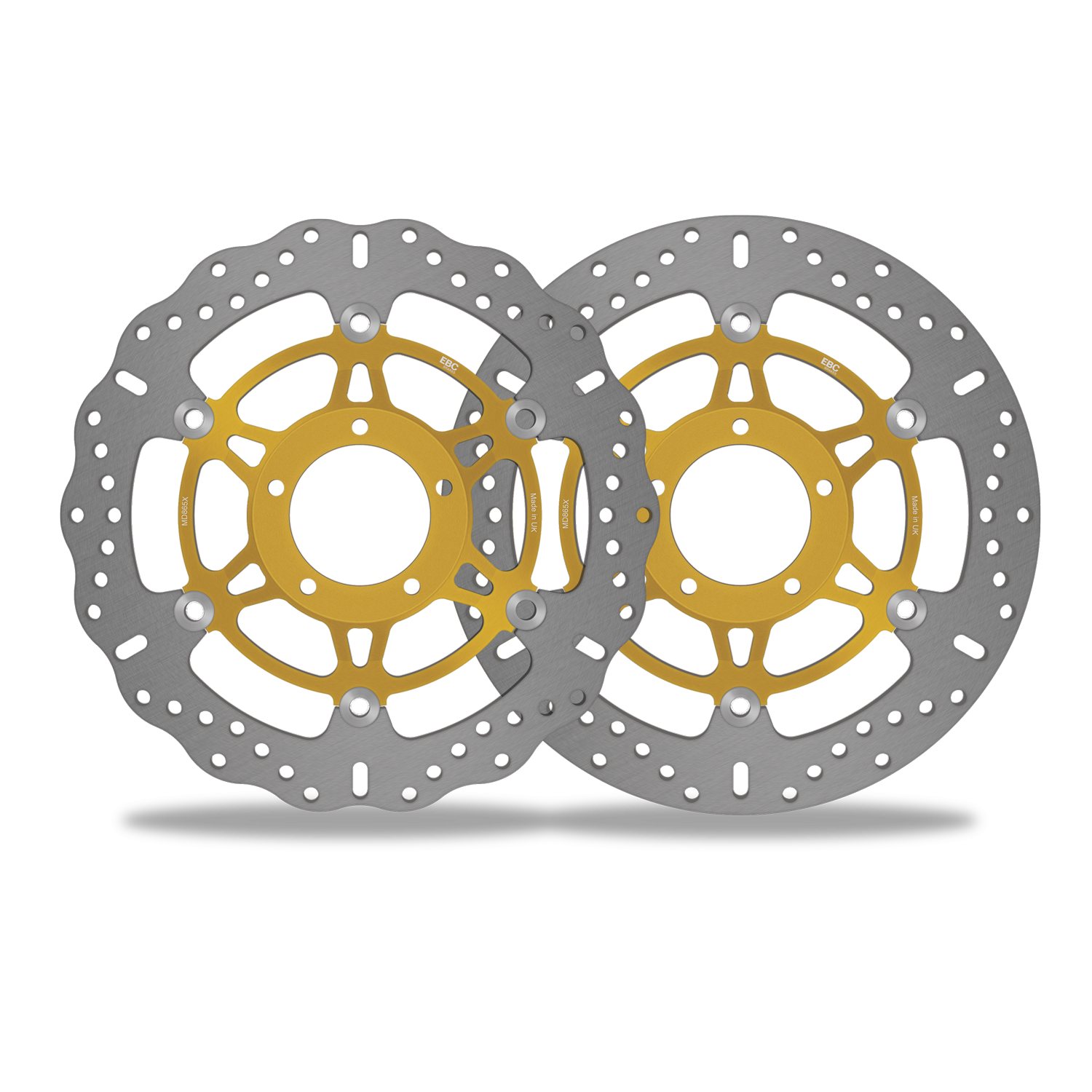

Ultra-lightweight EBC Brakes X series floating front MC rotors since their introduction has become one of the world’s best selling lightest and best-performing rotors available for all modern sportbikes, available from EBC Brakes distributors around the world.

MC Brake Rotors

X and XC floating motorcycle rotors are lightweight replacements for original OEM units. Precision made in the United Kingdom to fine tolerances for durability and perfectly balanced, eliminating vibration. EBC Brake rotors are assembled with our patented Square Drive button system further extending rotor life and braking performance.

- X rotors feature full circle, circular rotor blades

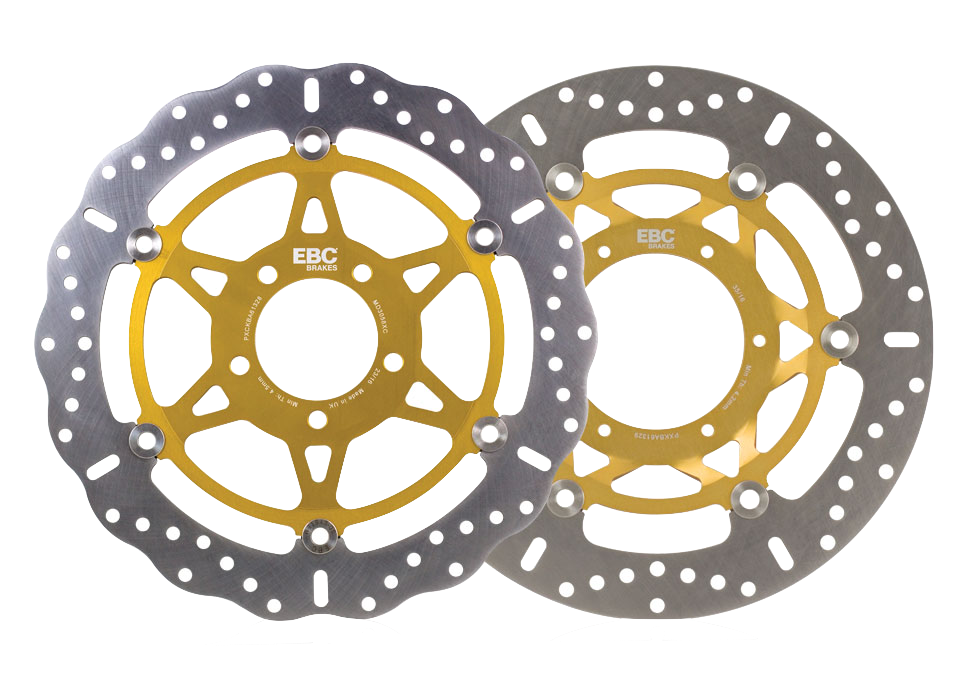

- XC rotors feature a contoured lighter weight profile.

X Series Floating Rotor

Both Floating MC rotors feature mill hard stainless steel high friction rotor blades for maximum brake effect and are the direct size for size replacements for OEM rotors. Both designs are also true fully floating units, offering more inside to outside float tolerance than any other rotor on the planet.

Do not confuse floating rotors with rotors that have loose blades or buttons. Neither the button nor the rotor blades should move. If this happens, pad “knockback” is likely to occur and the brakes will likely become spongy. Float refers to the ability of thermal expansion from the outside to the inside. This is what the EBC X and XC rotors offer and cannot be achieved with any other rotor.

XC Series Floating Rotor

Floating MC rotors feature EBC Brakes unique and patented S-Drive button system which features square sided rivets captured in square drive pockets on the rotor and hub which allow the outer rotor blade to expand and contract freely under the heat of braking without suffering rivet lock. As the design of Motorcycles progressed over the last 10 years with machines getting lighter, more powerful and faster the demand on Motorcycle brakes has increased. Great technical forward movements such as 4 and 6 piston calipers and more recently the radial caliper have helped stop motorcycles faster but there has been, until now little progress made on brake rotors. There have been attempts to reduce weight on rotors, usually by drilling more holes in the rotor blade but always the OEM builders have used the boring “Round Style” rivet or drive button technology.

This outdated method of building rotors has now been consigned to the history books as EBC Brakes proudly announces the arrival of a new and patented design of drive button known as the SD System. SD stands for Square Drive which describes the button designs used in the new EBC X and XC rotors.

Technical Information

X Series - Fully floating front rotor

Rivet lock is the term used when rotors heat up under heavy braking and the rotor blade contacts the (normally circular) rivets that separate the inner rotor hub and the outer rotor blade. The new EBC Brakes system completely eliminates this problem area which causes 100% of the failures of rotors suffering from distortion and brake vibration. These rotors are equipped with the new EBC Brakes patented S-Drive system.

What is S-Drive? EBC Brakes’ square sided drive button system completely eliminates the possibility of rotor distortion, extending rotor life and improving consistency of braking effectiveness.

XC Series - Fully Floating Front Disc/Rotor

EBC ProLite XC contour rotors are the toughest yet lightest sport and race brake rotors you can put on your bike for a variety of reasons. We explain why these are the best.

- The contoured profile reduces weight by 7.5% without reducing the actual “cooling mass” of the rotor.

- New German mill rolled heat-treated stainless steel rotor blade.

- The vertical scraper slot system removes dirt, dust, and debris quickly from the braking area.

- A unique fully overlapping vent hole pattern reduces weight, cleans the rotor blade, and helps deglaze pads.

- New Patented Stainless Steel SD (square drive) button drive system, prevent warping and vibration totally system – click here for full tech info.) Ultra-lightweight ductile alloy center hub.

- The use of the SD system allows fewer drive buttons, in the case of EBC we are down to six buttons

- Full stainless components, no rusty parts, and that’s guaranteed.

For over 30 years EBC has been the number one in brake pads and these new XC Contour rotors stake the EBC claim to the rotor market leadership. These rotors can be used on the street, track-days or Road Racing and hundreds of privateer teams all over the world race these.

Can't find what you're looking for?

The EBC Brakes team is always happy to help. If you can't find what you're looking for, please don't hesitate to get in touch via our Contact page. But be sure to check our FAQ's first, in case your query has already been answered.